SCALE GUARD

Water Scales

Water Scales and HVAC Industry

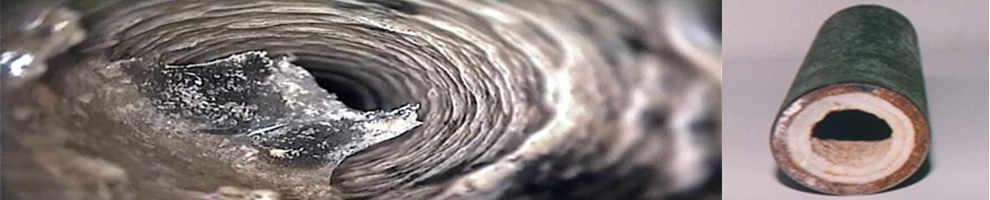

- Scale formation can clearly be seen on the inside wall of the pipe. Remember this is only after 30 days

- Only 11/416 inches of scale will reduce cooling system heat transfer efficiency by 40%

- The performance of a cooling tower degrades when the efficiency of the heat transfer process declines. Scale fouling (formation) results in reduced diameter or blocked pipes, reduced heat transfer efficiency, seized pumps, inoperable valves, misleading meter readings, defective-heating elements etc.

EFFECT OF SCALE DEPOSITS

THE BUILD UP OF SCALE LEADS DIRECTLY TO:

1. Increase in Electricity Consumption.

Costs |

|||

Hardness |

Light |

Moderate |

High |

Tonnage |

0-200ppm |

200-400ppm |

400ppm and more |

120 TR |

66 |

145 |

211 |

250 TR |

136 |

300 |

435 |

400 TR |

220 |

485 |

706 |

Note: all costs are in Rs. 000’s

Scale formation acts as insulator i.e bad conductor of heat resulting in the scale formation in the condenser tubes, increasing electricity consumption as much as 10%

2. Reduction in life of equipment:

Frequent descaling with chemicals not only damages the copper tubes but it also reduces the life of the cooling unit by 1- 2 years. Chemical dosing is also hazardous which involves safety risk and also employee health issues

3. Damaged copper tubes and increase maintenance:

As the descaling is done by acids, it attacks copper tubes and during the rodding of tubes they get punctured. This can cause regular expenses to the tune of Rs.15,000/= to Rs. 20,000/= per tube

4. Less cooling effect and shut down for descaling:

With scale formation cooling efficiency reduces and the need arises to shut down for maintenance purposes.

FACTORS RESPONSIBLE FOR FORMATION OF SCALE

1. Calcium content of water.

2. Alkalinity of water.

3. pH of water.

4. Temperature of re-circulation water.

5. Higher concentration of solids (TDS).

Calcium and magnesium hardness define the scaling tendency of the water. Total alkalinity, pH and temperature define the concentration of carbonate and bicarbonate ions and also the solubility of calcium carbonate. All of these must be within acceptable ranges for each system to ensure scale-free operation. Concentration of sulphate and silica must also be controlled to prevent formation of gypsum and silica scale.

Several indices are used to describe the behaviour of Hardness salts in water, oil, or gas mixtures. One such index in Langelier Index